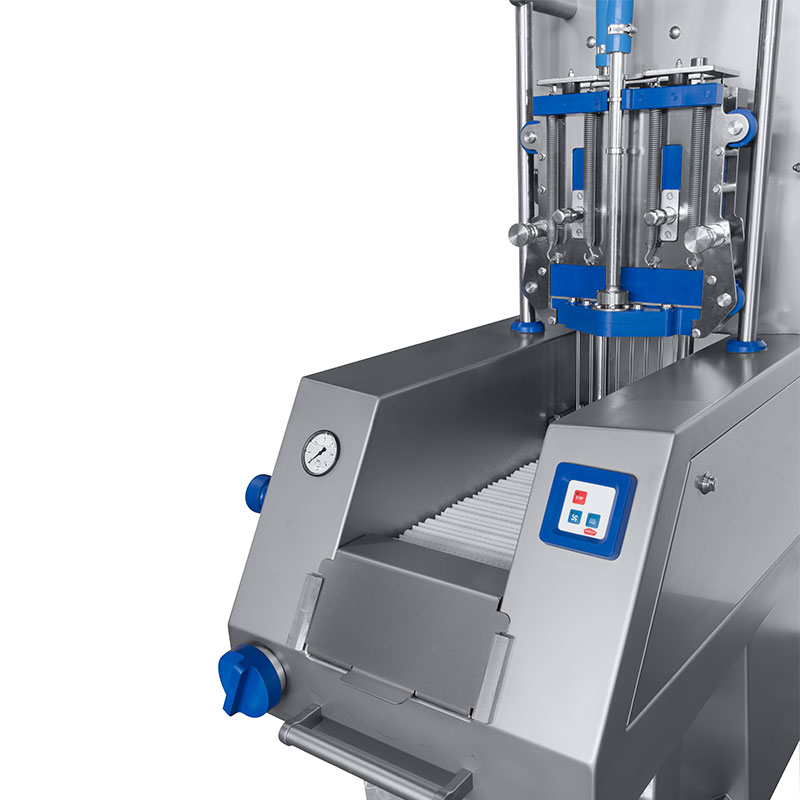

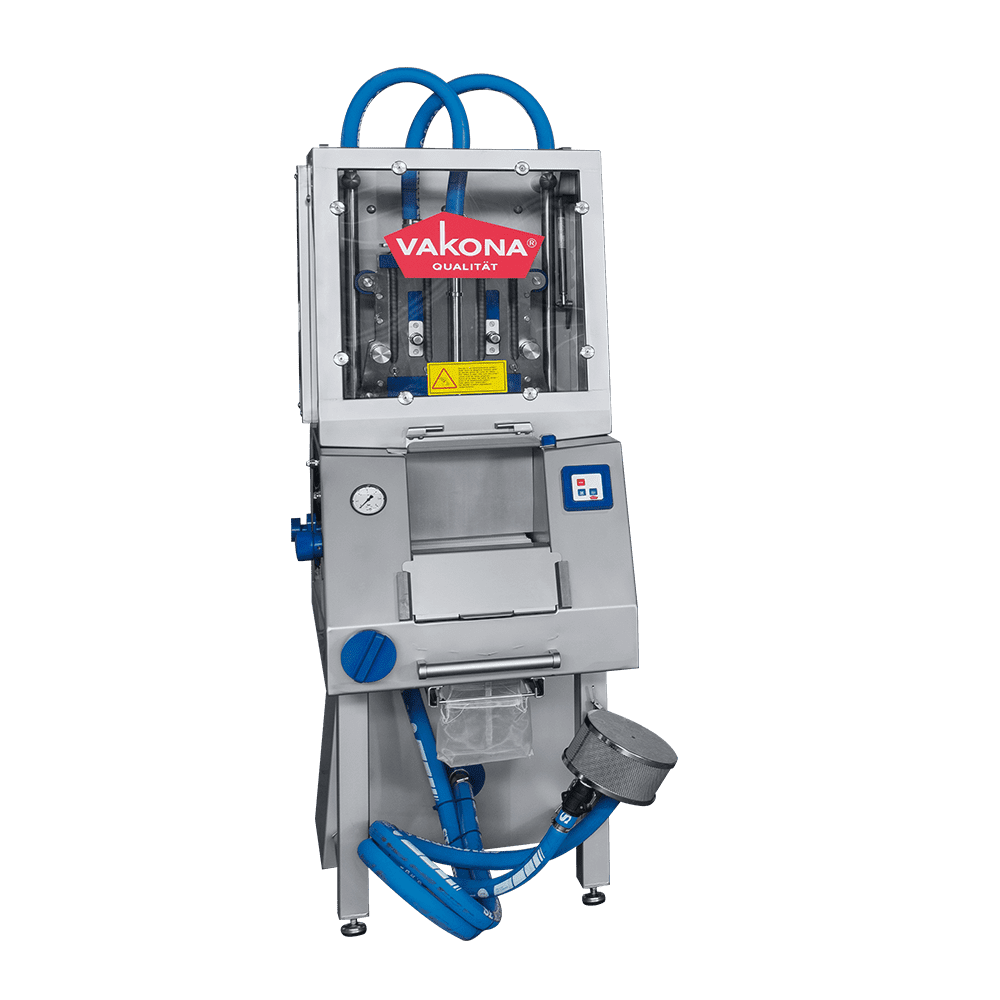

Pickle injector

Pickle injector PI 17 V

The automatic brine injectors are specially designed for the requirements of the craft and SMBs.

Their outstanding features are:

- Rugged construction

- Compact design

- High injection accuracy

- Easy operation

- Easy to maintain

- High flexibility

- Easy to clean

Standard equipment:

- Direct mechanical drive for needle head and belt above the pickling compartment

- Precision needle heads with quick-change needle bridge system

- Mechanical suspension of each needle for products with bones

- Complete separation of the entire pumping cycle from all electromechanical components

- Standard stainless steel centrifugal pump

- Product-related pump selection

- Pre-filter system

- Special conveyor belt made of polyethylene, easy to remove

- Injection pattern can be varied by mechanically changing the conveyor belt feed settings

Optional equipment:

- semi-automatic filter system VHF

- H version for fish and poultry

- steaker knife device for products without bones

- manual injection connection

Dimensions and technical data of the pickle injector PI

| PI 17 V | PI 21 V | PI 26 V | PI 51 V | |

|---|---|---|---|---|

| Injection needles | 17 | 21 | 26 | 52 |

| Length | 1400 mm | 1400 mm | 1600 mm | 1600 mm |

| Width | 560 mm | 700 mm | 800 mm | 800 mm |

| Height | 1750 mm | 1760 mm | 1850 mm | 1850 mm |

| Length of conveyor belt | 1150 mm | 1100 mm | 1250 mm | 1250 mm |

| Length of conveyor belt | 265 mm | 280 mm | 345 mm | 345 mm |

| Max. product clearance | 180 mm | 210 mm optional 240 mm | 210 mm optional 240 mm | 210 mm |

| Working height | 820 mm | 780 mm | 930 mm | 930 mm |

| Connected load | 1,5 kW | 1,5 kW | 2,2 kW | 2,2 kW |

| Weight | 290 kg | 320 kg | 450 kg | 480 kg |

| Due to the versatile optional equipment, the machine pictures shown may contain deviations. If you have questions, please contact us. | ||||

Dimensions and Technical Data – Technical alterations are subject to change – Exact mounting dimensions should be obtained